Product Overview

XGN2-12 box-type fixed metal-enclosed switchgear (referred to as switch cabinet) for a three-phase AC 50Hz system 3.6,7.2,12KV as acceptance and distribution of electric energy, suitable for frequent operation occasions, the bus system as a single bus (can derive a single bus with bypass and dual bus architecture). The switchgear line with national standards GB3906-91 "3 ~ 35KV AC metal-enclosed switchgear" and GB standard IEC298 requirements, and there are two proposed "Five Anti" lockout feature.

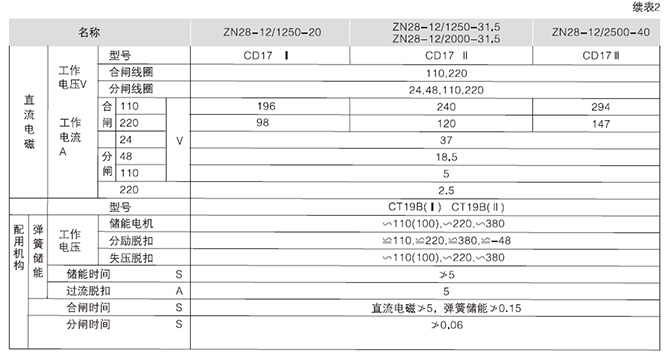

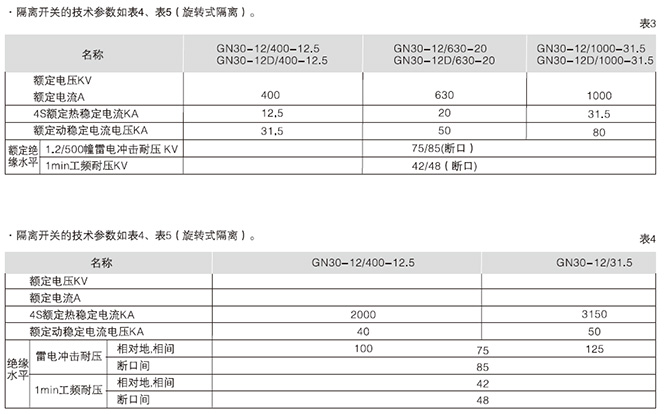

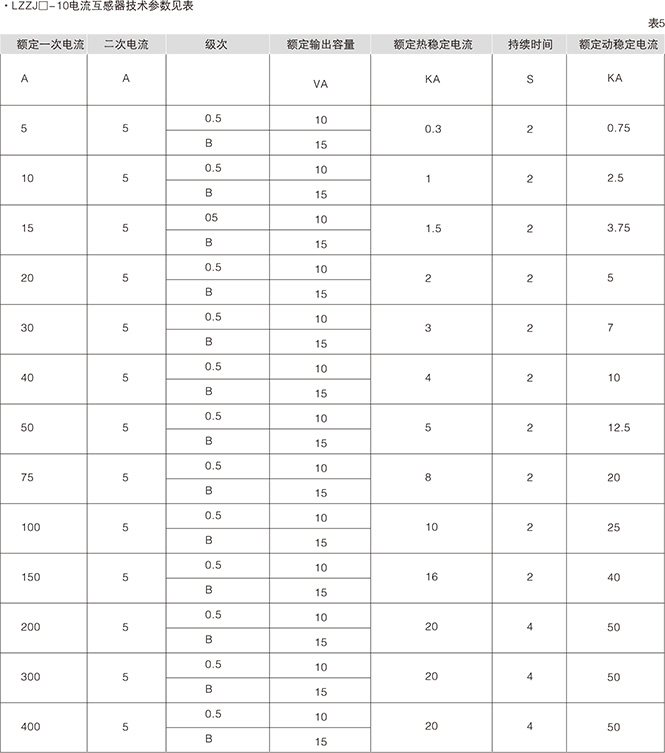

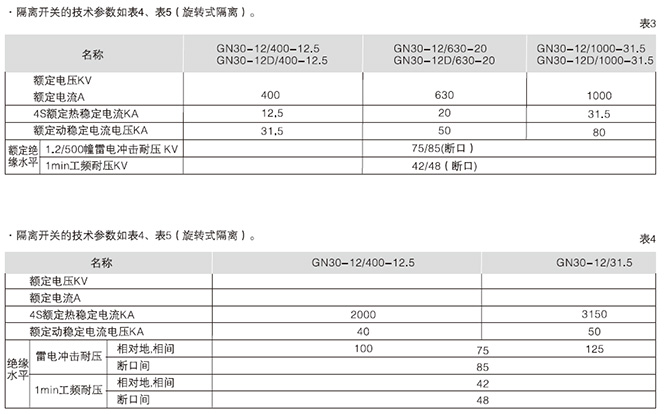

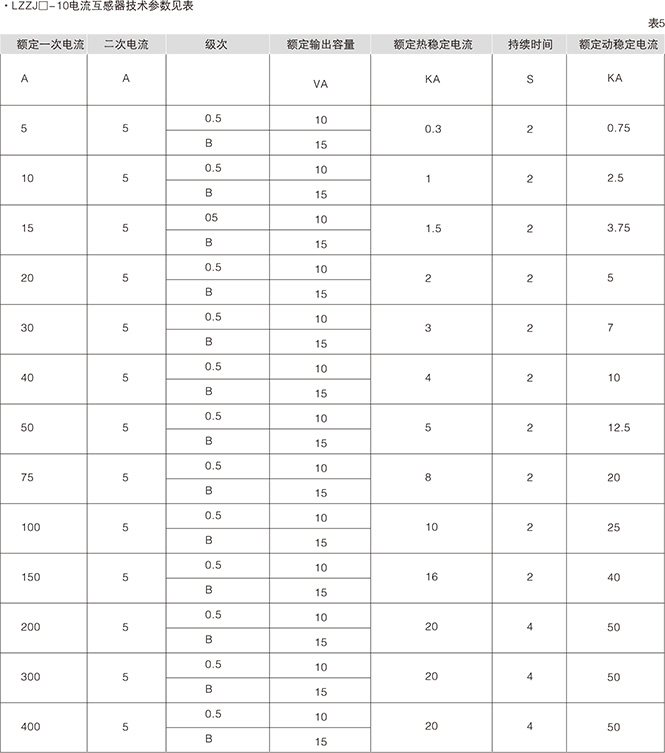

The switchgear main switch ZN28-12 series of vacuum circuit breakers, equipped with CDI7 series electromagnetic actuator or CT19 Series spring actuator, rotary isolation switch with GN30-12 GN22-12 isolation switch or high-current isolation switch series products.

Use of the environment

◆ The ambient temperature limit + 40 ℃; lower limit of -5 ℃;

◆ altitude less than 1000m;

◆ mean daily relative humidity less than 95%, on average less than 90%;

◆ earthquake intensity does not exceed 8 degrees;

◆ no fire, explosion, serious pollution, chemical corrosion and severe vibration place.

◆ environmental conditions beyond the above, the user should consult with the manufacturer.

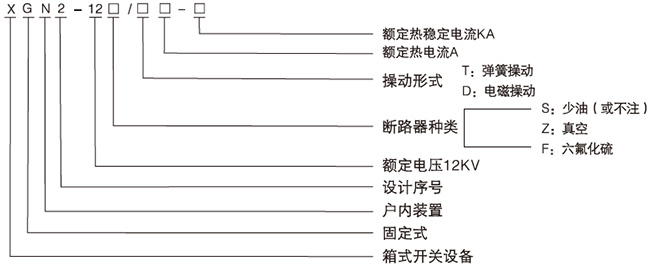

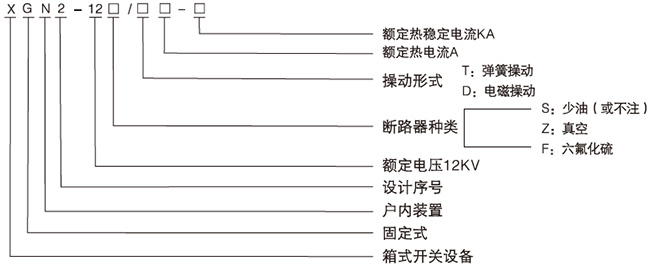

Model and meaning

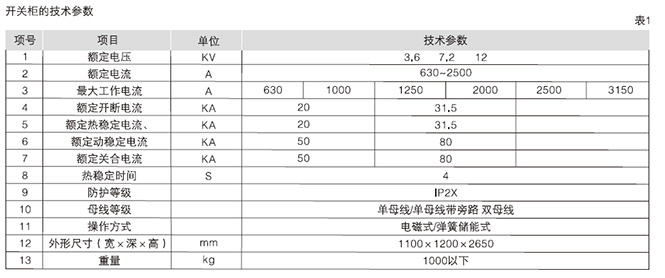

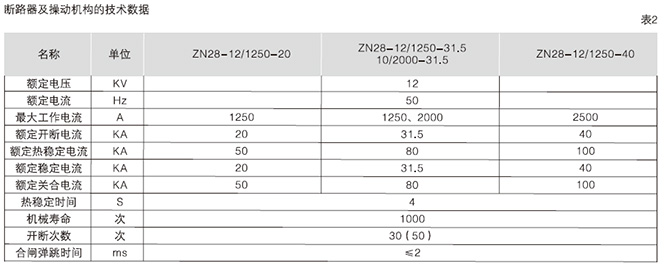

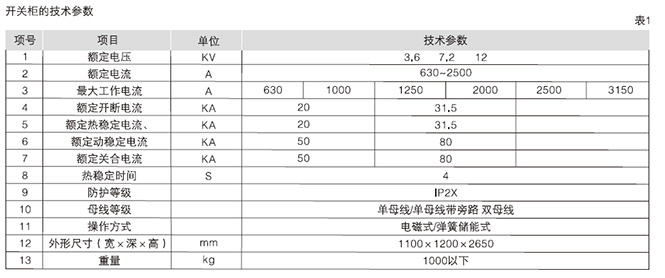

Performance Parameters

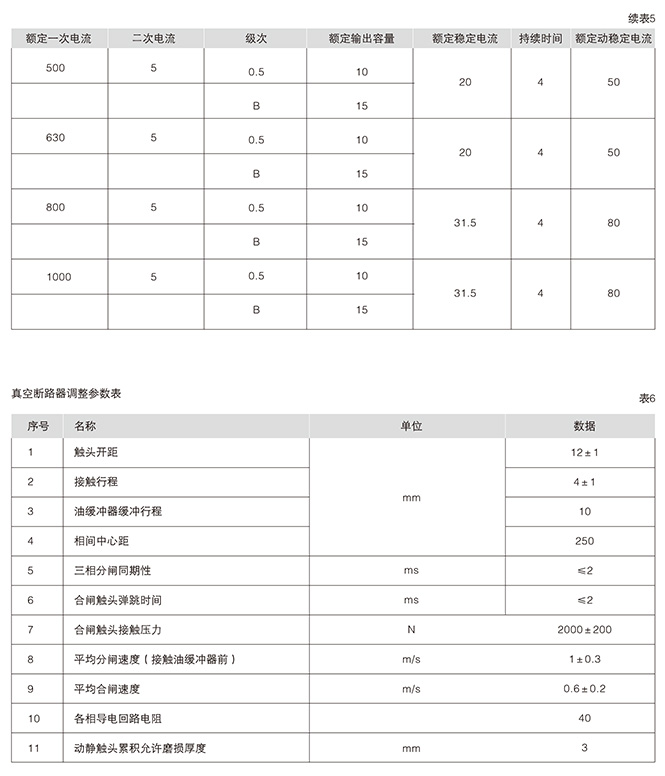

◆ switchgear technical data in Table 1;

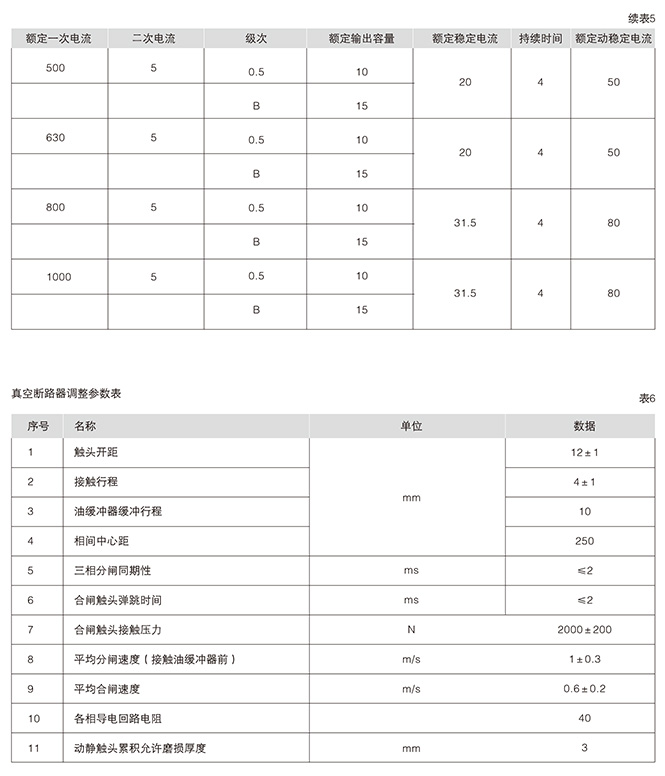

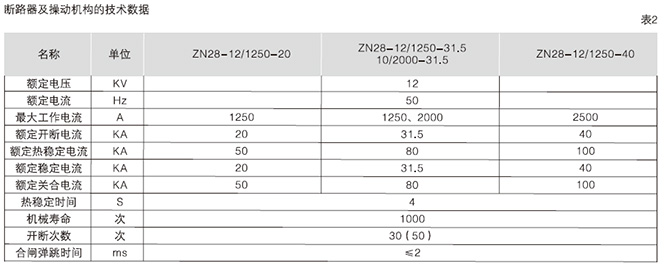

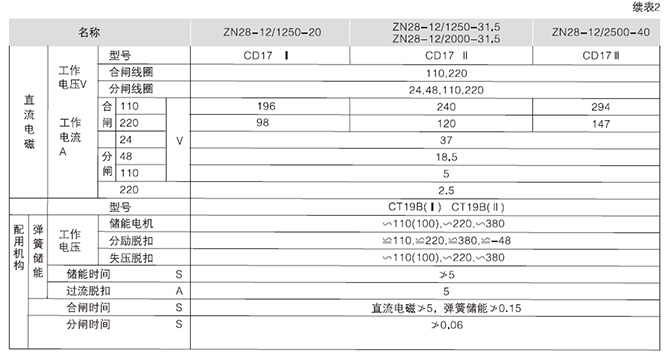

◆ Technical Data breaker and operating mechanism in Table 2, the vacuum breaker switchgear based.

◆ grounding switch technical data, technical parameters of the ground should be able to switch to the corresponding parameters with isolation switch, grounding switch so dynamic and thermal current, the contact pressure with the corresponding separated off from the same, but the distance between Earth switch fracture does not less than 125mm.

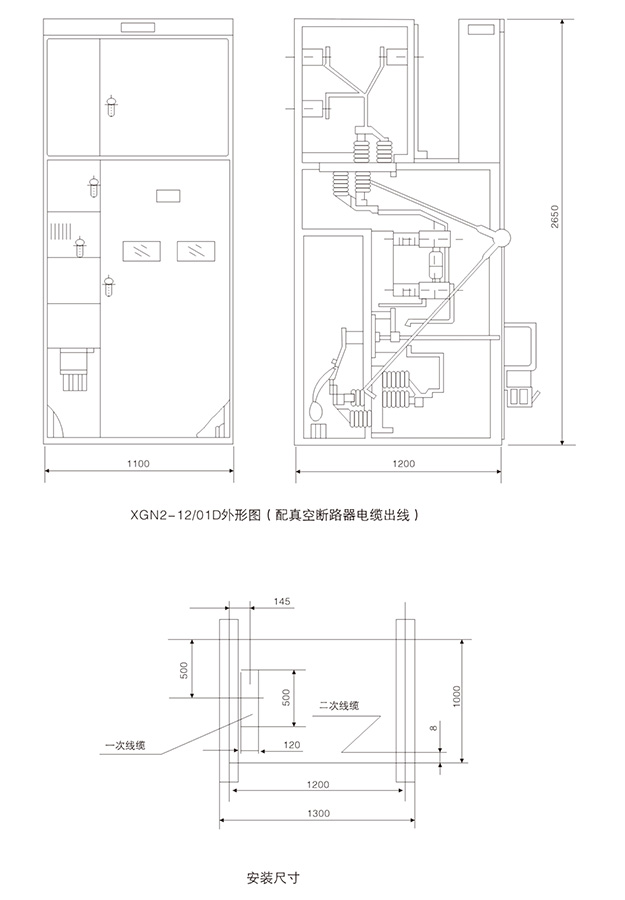

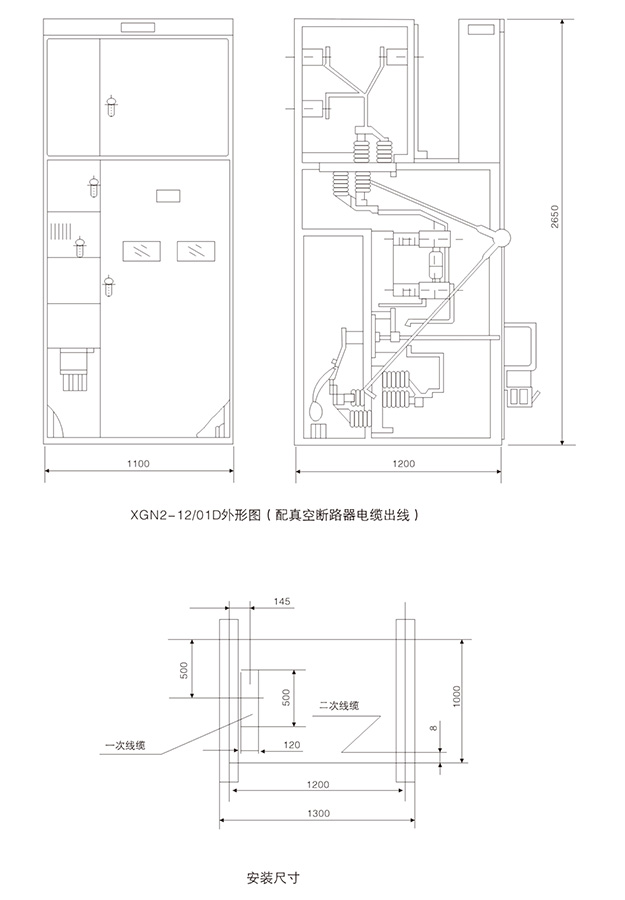

XGN2-12外形安装图

◆ switchgear installation dimensions see chart

◆ Structure

The metal-enclosed switchgear for the box-type structure, the cabinet frame from angle iron welded cabinet is divided into circuit breaker room, bus room, cable room and relay room. Separated by a steel plate between the chamber and the chamber.

Circuit breaker compartment in the lower cabinet, drive circuit breakers connected by rod and actuator; under current transformer and circuit breaker terminal connected to the current transformer isolation switch with terminal connection on the terminal and the circuit breaker isolation switch terminals want to connect the circuit breaker compartment also features a pressure release channel, if an internal arc occurs, the gas can be released through the exhaust passage pressure.

After the bus room in the upper cabinet, the cabinet in order to reduce the height of the bus was a product shaped arrangement, with porcelain insulators support flexural strength of 7350N, the bus and the end of the isolation switch wiring connections.

Cable compartment in the lower part of the rear of the cabinet, cable indoor support insulators can be provided with monitoring devices, cables fixed to the bracket. For the wiring of contact solution is that the room was to contact the cable room.

Breaker operating mechanism being installed in the lower left position, the top of the isolation switch operation and interlock mechanism.

Switchgear for double-sided maintenance, relay room in front of the secondary component overhaul, maintenance actuator, maintenance on the bus and the cable terminal mechanical interlock and transmission parts, repair circuit breakers, back in the breaker room and cable room are equipped with lighting.

Underneath the front of the cabinet is provided with a width direction parallel to the ground copper bus bar, its cross-section 4 * 40mm2 mechanical interlock: In order to prevent the division with a load isolation switch; prevent misclassification error breaker; prevent straying a little space; prevent grounding switch live together; prevent closing with ground knife. Switchgear with the corresponding mechanical interlock, mechanical interlock operation principle is as follows:

◆ power operation (Run → overhaul)

Switchgear in the working position, namely the upper and lower isolation switch, circuit breaker is closed, the front and back doors locked shut, and is charged to run into, when the small handle in the working position.

First off the circuit breaker, and then pull the small handle to "breaking lock" position, then the circuit breaker can not switch on, the operating handle into the hole under quarantine operation, from the pull-down, and then push up the grounding switch is closing position, then can pull the small handle to "overhaul" position, the first to open the front door, take out the back door if the back door open, power operation is completed, maintenance personnel can breaker room and cable room for maintenance and repair.

◆ power transmission operations (maintenance → Run)

Ruoyi overhaul is completed, you need to send power, its operating procedures are as follows:

The back door locked shut, shut the front door after removing the key, pull the small handle from the service position to "divide lock" position, when the front door is locked and can not switch on the circuit breaker, grounding switch operation hole insert with operating handle, from on the drop-down, the grounding switch is in the OFF position, the operating handle winning, and then insert the isolation operation hole, pushed up from the bottom, so that isolation in the closing position, remove the operating handle, pull the small handle to work position, then you can switch on the circuit breaker.

Installation, adjustment and maintenance

◆ Installation

◆ power vacuum circuit breaker in the closing minutes when produced, up, down about 7840N, this data provides the basis for estimation of stress during design basis.

◆ foundation

Referring to Figure 2 basis switchgear careful design and construction, the foundation should be flat.

◆ Setup and Notes

a. The switchgear according to the arrangement is placed on the basis of a set of adjusting straightness good switchgear, vertical, horizontal degrees and with M12 bolts or by welding methods switchgear fastened on the basis of the slot

Steel on

. b with M12 × 30 bolts link between the cabinet;

. c install the main bus, bus room to open the top cover plate installed after a good tight jacking plate, connecting busbar contact surfaces;

d install a cable to connect to the bus contact surface should be smooth, the contact surface coated with petroleum jelly after neutral, and tighten the application partition after the cable compartment cable construction and the cable trench packer.;

. e indirectly connected cabinet bus, so arranged along the direction of fused switchgear, and protective earth grounding checks whether there are any omissions, whether continuous conduction ground loops, grounding resistance should be less than 1000μΩ;

f. install secondary circuit cable, the cable from the left side of the body at the end penetration, along the side wall into the relay room, divided to the corresponding terminal block, the construction should pay attention to the cable numbers, terminal numbers do not leak or wear Chuancuo, two second cable construction finished, do not forget the cover note cable holes.

◆ acceptance test and put into operation before the preparatory work

◆ Acceptance Test Project

. a model based on electrical components installed inside check ordering information, specifications are consistent;

. b check for loose fasteners, found loose and should be tightened;

. c Check the bus connection, the contact is tight and, if exposed, should be repaired;

. d manual isolation switches, circuit breakers, and other mechanical interlock program 3-5 times, no stuck phenomenon should be flexible, and accurate action, the program is correct;

. e Check the circuit breaker, the mechanical properties of the isolation switch, meets the requirements of its own provisions;

. f Check the secondary wiring meets the requirements of the drawings, the main circuit is not energized in the case of the secondary circuit is energized action test, compliance with the requirements of secondary wiring diagrams;

g. secondary circuit dielectric strength test between the conductor and the outer casing, applying AC 50HZ, voltage 2000V, which lasted 1min, there should be no breakdown discharge phenomenon, the secondary circuit in the electronics portion of the test voltage production plant with a user agreed ;

h. the main circuit power frequency voltage insulation test, in accordance with the relative and alternate rated voltage switchgear, according to GB311. 85% of the specified value for 1min should be no breakdown flashover.

◆ operational preparations

. a need oiling activities at the site should note lubricants;

. b connected to control, signaling, lighting and other power;

. c in isolating switches, circuit breakers, etc. while in sub-gate status, which means that motivated breaker cabinet;

. d voltage switchgear transformer isolation closed, check the voltmeter is correct, if the right to go ahead;

. e Close the arrester, isolation transformers and related auxiliary appliances make operational the station;

f. Close the feeder circuit breaker of turn, check the meter is correct.

◆ maintenance and repair

After ◆ ◆ switchgear into operation, monitoring and maintenance work as follows;

. a cleaning various parts of the dust, especially dust insulating surface;

. b overhaul program locks and mechanical connection pins, remain flexible and reliable operation, the program is correct;

. c by circuit breakers, disconnectors, operating mechanism and other electrical requirements for maintenance and debugging;

. d check the electrical contact area, contact situation is good, detect ground loops, maintain continuous conduction;

e. fastening each screw, pin.

Run ◆ product acceptance and custody

◆ product can be carried out by the factory packaging and shipping after inspection, packaging, product bolted to the bottom row, during transport, except for upright not upside down, tipping, rolling, fell.

◆ by product packing list, on the whole, accessories for acceptance.

◆ before installing warehouse storage products, should prevent rain, parts. Shall be deposited in the Treasury of the original packaging, not damp; not disassemble electrical components and parts.

Random files

◆ random files include;

◆ product certification;

◆ installation manual;

◆ second construction wiring diagram;

◆ packing list.

Wearing parts, accessories and spare parts

◆ proper circuit breakers and other electrical consumables;

◆ switchgear wearing parts, in consultation with the manufacturer determined by the user;

◆ switchgear accessories, spare parts for the type of table, use can be ordered from the manufacturer.

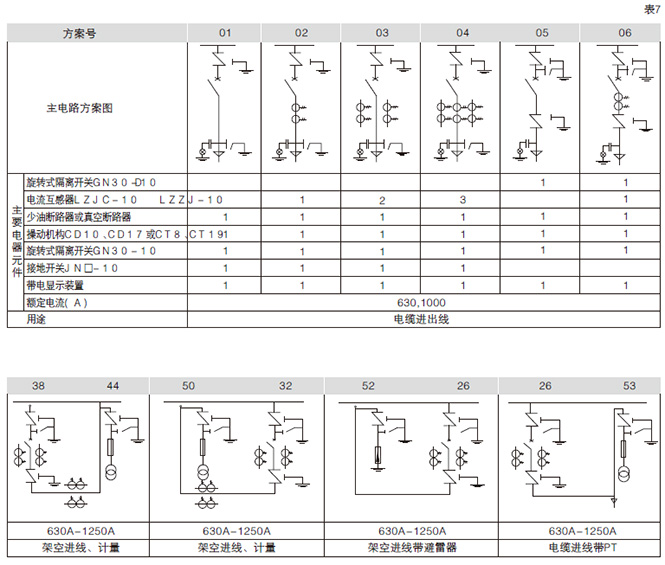

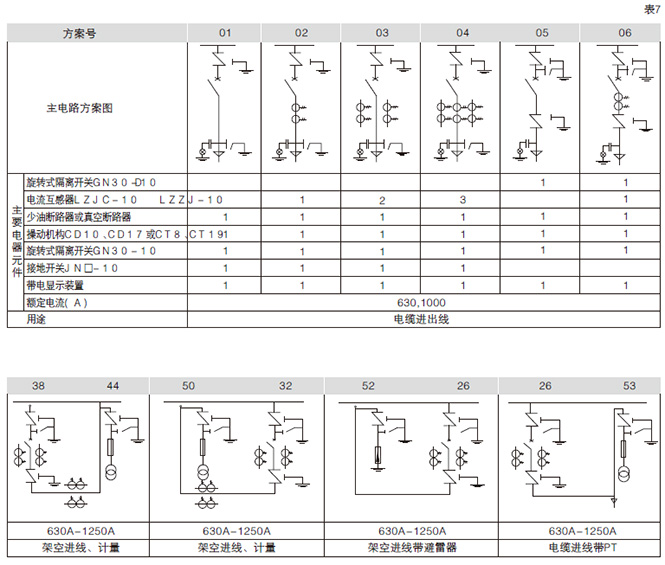

The main circuit combination regimen example

Ordering Information

Users must provide the following information when ordering;

◆ main circuit number and a system diagram, Pareto chart;

◆ secondary circuit wiring diagram, terminal layout map, such as when the terminal is no arrangement diagram specified by the manufacturer;

Model ◆ electrical switchgear components, specifications, quantity;

◆ main bus, bus support materials, specifications otherwise specified by the manufacturer supply;

◆ switchgear using special environmental conditions, should be made when ordering;

◆ need accessories, spares, should submit its type and quantity.