Products

SC (B) 10 type cast resin dry type power transformer is the best low-noise performance of low-loss dry-type transformers, distribution transformers as a variety of replacement products, is all kinds of dry-type transformers in performance one of the best products, especially for important places of urban power grids, high-rise buildings, business centers, theaters, hospitals, hotels, tunnels, subways, underground stations, laboratories, stations, terminals, airports, such as promoting the use of a combination of the substation.

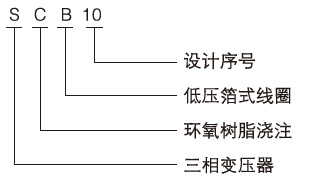

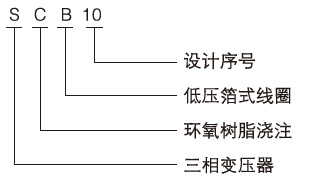

Type Meaning

Features

Low Loss: Product load loss than the latest national standard GB / T10228-2008 "dry type power transformers technical parameters and requirements" reduced by more than 35%, excellent energy-saving effect, run the economy, maintenance-free.

Low noise: noise levels than existing product professional standards JB / T10088-1999 "6-220KV scale transformers sound level" low 10-15 decibels.

Low PD: resin mixture is stirred using the most advanced methods and vacuum degassing film two technologies, so that the mixture and stir bottom eliminates the bubble mixture inside. Products only low partial discharge, can be controlled in 5PC less.

High and low voltage coils are in a vacuum and pressure casting, resin insulated both with full encapsulation, but also has an interlayer between turns impregnation. Casting body has a dense solidified structure, fire, explosion, do not pollute the environment. Insulating material such as glass fiber wound coils have self-extinguishing properties, not because a short circuit arc, the resin does not produce heat under toxic gases.

High mechanical strength: the resin filler with the expansion coefficient of the small differences in the pouring body, curing shrinkage, internal stress, high hardness of the cured product, in the high and low voltage coils of the inner and outer surfaces of epoxy resin coating layer, is placed preformed reinforcing material, just like reinforced concrete has the same compact structure, and thus also the mechanical strength greater than pure epoxy, can withstand sudden short-circuit the role of electric power without damage.

High electrical strength: high, low voltage coil are pouring sake in a vacuum sealing structure, good insulation properties and arc resistance and moisture resistant, can withstand atmospheric over-voltage, over-voltage, transient over-voltage electrical voltage and long-term work of strength, power frequency withstand voltage for the strong type.

High heat intensity: high and low voltage coils are thin epoxy resin coating insulation and thermal conductivity coefficient, good heat dissipation, cooling generally use natural air cooling (AN), forced air cooling system can also be configured (AF ). Heat insulation up to H level, the average temperature rise allowed 12.5K, extreme temperatures up to 180 ℃, with high heat intensity, life of more than 30 years.

Small size, light weight, low footprint, low installation costs, not to consider the drain tank, fire prevention and fire-fighting facilities, such as backup power. Dispersible installed in the load center, close enough power point, thus reducing cost and saving expensive line Low infrastructure costs.

Housing material made of stainless steel or aluminum. Protection class IP20 and IP23. IP20 enclosure to prevent the diameter greater than 12mm of solid foreign objects entering the transformer for further security. IP23 enclosure but both prevent vertical line with a 60 ° angle of water droplets within the inflow applicable running outdoors.

Temperature control system installed by the temperature controller and the hottest products that PTC temperature element constitutes the upper end of the low voltage winding to realize the transformer temperature measurement and control, if the running due to an overload or malfunction caused by the transformer winding temperature is too high, the temperature controller alarm signal when the temperature exceeds the trip on their own security value. By temperature controller determines the level of investment or the cooling fan is switched according to the winding temperature using forced air cooling. Temperature hot temperature display system displayed directly in the process of winding transformer operation, and temperature control systems can be used in conjunction.

Technology standard

◆ GB 10228-2008 hall "dry type power transformers and technical requirements."

◆ GB6450-1986 "dry type power transformers"

◆ IEC726 "flat-type power transformers" (International Electrotechnical Commission standard)

The first part ◆ GB1094.1-1996 "Power Transformer"

General

◆ JB / T1 0088-1999 "6-220KV scale transformers sound level"

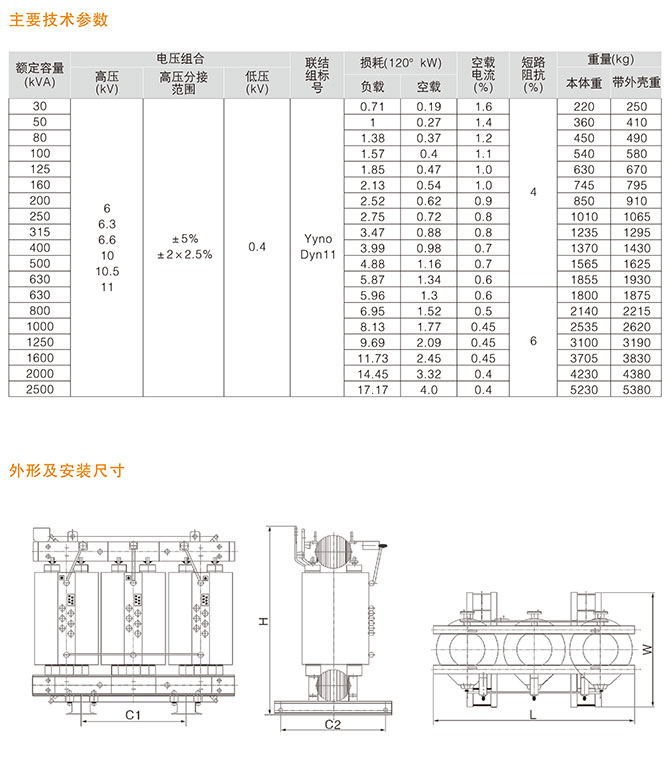

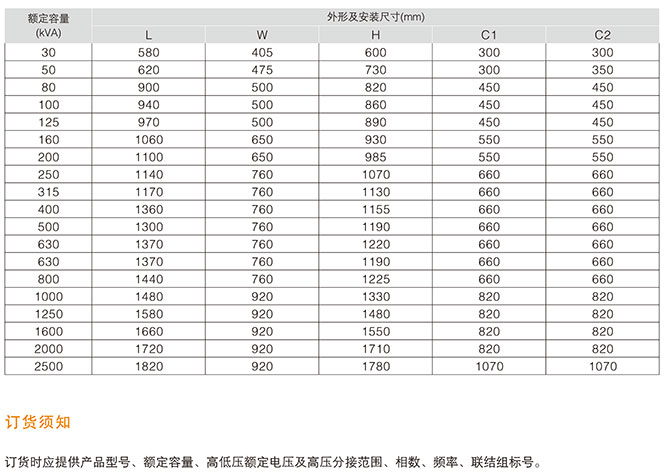

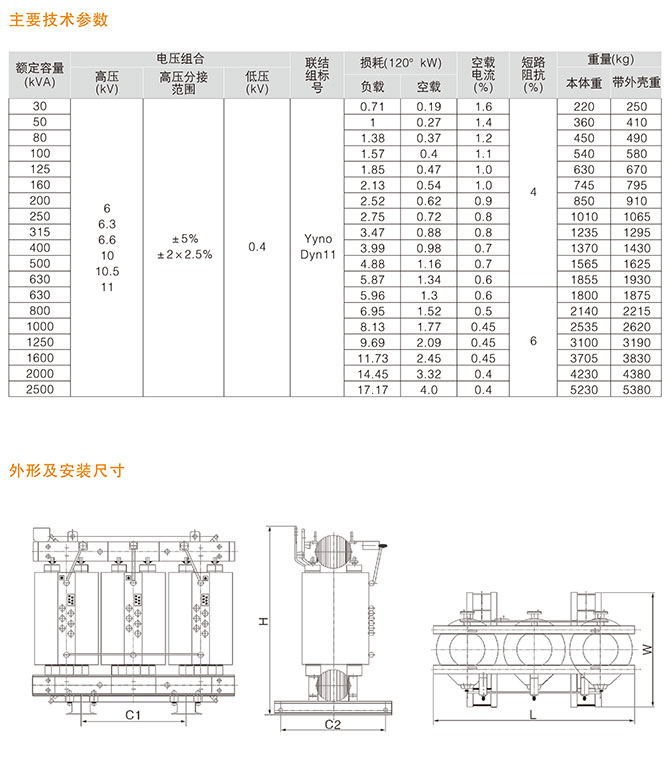

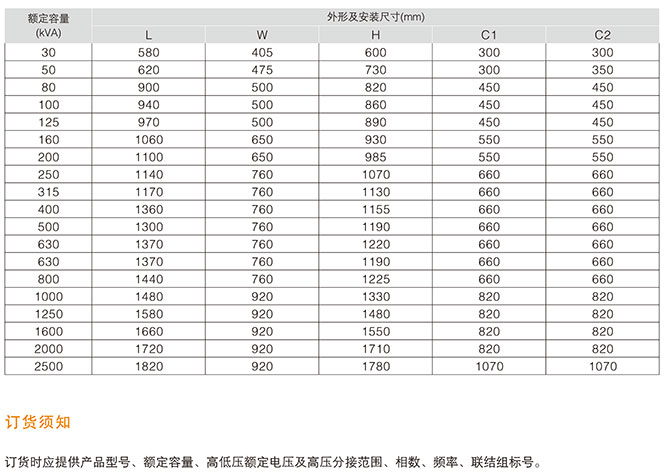

Technical Specifications

Capacity range: 20-6300KVA;

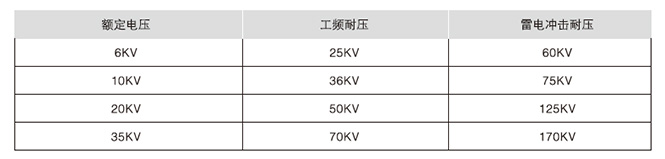

◆ Voltage rating: 6KV, 10KV, 20KV, 35KV;

◆ voltage mode: ± 2 × 2.5% or ± 5%;

◆ Frequency: 50Hz;

◆ Phase: 3 phase or single-phase;

◆ impedance voltage: Standard impedance voltage see technical data sheet;

◆ conditions: ambient temperature not higher than 40 ℃, relative humidity up to 100%, no more than 1000 meters above sea level;

◆ Protection Notice: IP00 or IP20 (indoor), IP23;

◆ Insulation Rating: H winding allow an average temperature rise 125K;

◆ temperature limit: 180 ℃;

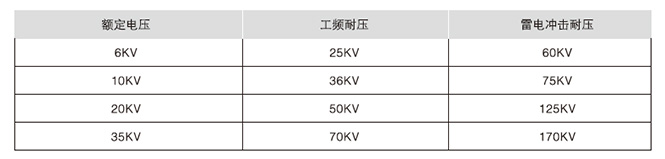

◆ insulation level.

Volume and temperature control devices: digital approximation of the three-phase low voltage winding internal temperature controlled cooling fan.

According to user requirements of special design and production, such as highland products, high-impedance products OLTC products.