Outline

KYN28-24 (ZK) (GZS1) armored withdrawable AC metal-enclosed switchgear (hereinafter referred to as "switching equipment"), for three-phase AC 50Hz power system for receiving and distributing power and circuit implementation of control, protection and monitoring.

Product meets the standards: GB3906-2006 "3.6-40.5kV AC metal-enclosed switchgear and control equipment", GB / T11022 "high-voltage switchgear and control equipment standards common technical requirements", IEC62271: 200 "52 less than the rated voltage 1kV AC metal-enclosed switchgear and control equipment ", DL / T404" indoor AC high voltage switchgear ordering technology. "

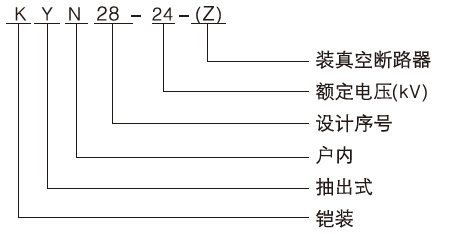

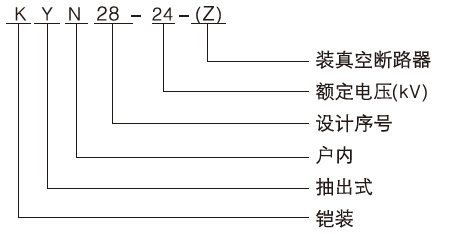

Model and meaning

Conditions of Use

◆ The ambient air temperature: maximum temperature 40 ℃, the lowest temperature -15 ℃

◆ Relative humidity: daily average of not more than 95%, the average vapor pressure not exceeding 2.2Kpa on average less than 90%, the average monthly water vapor pressure does not exceed 1.8Kpa

◆ Altitude: 1000m and below

◆ earthquake intensity: no more than 8 degrees.

◆ ambient air should not be obviously polluted corrosive or flammable gases, water vapor.

◆ no recurrent severe vibration.

◆ When environmental conditions than under normal use GB3906 provisions, negotiated by users and manufacturers;

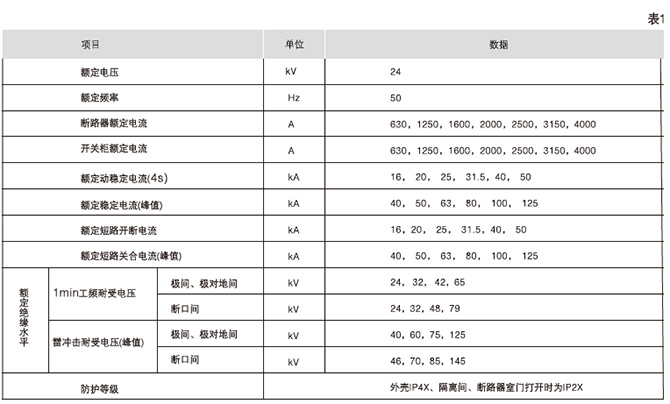

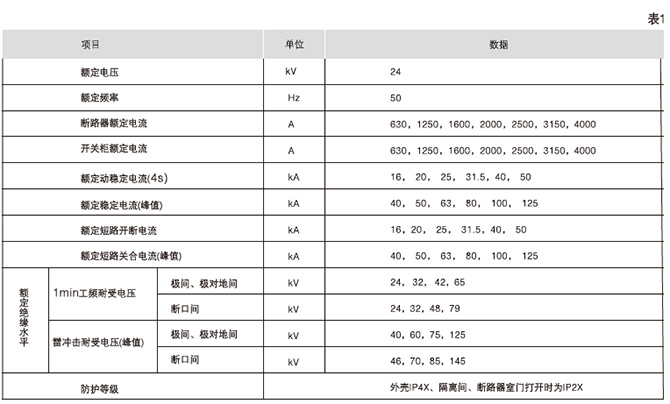

Technical parameters

Note: The current transformer short-circuit capacity to be considered separately;

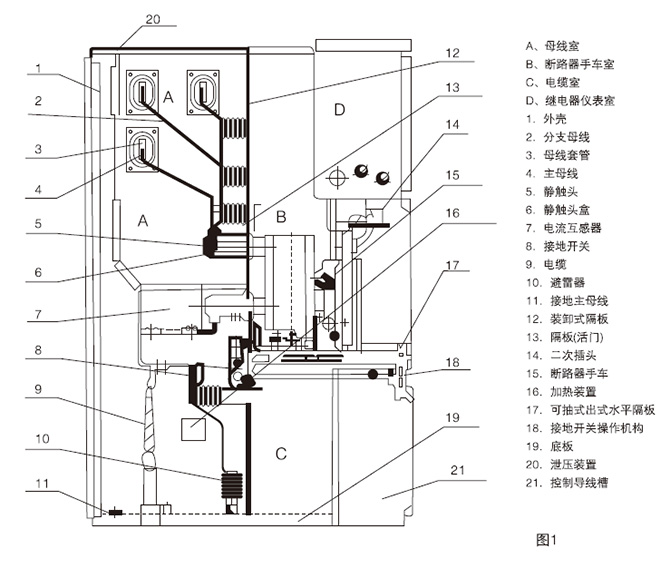

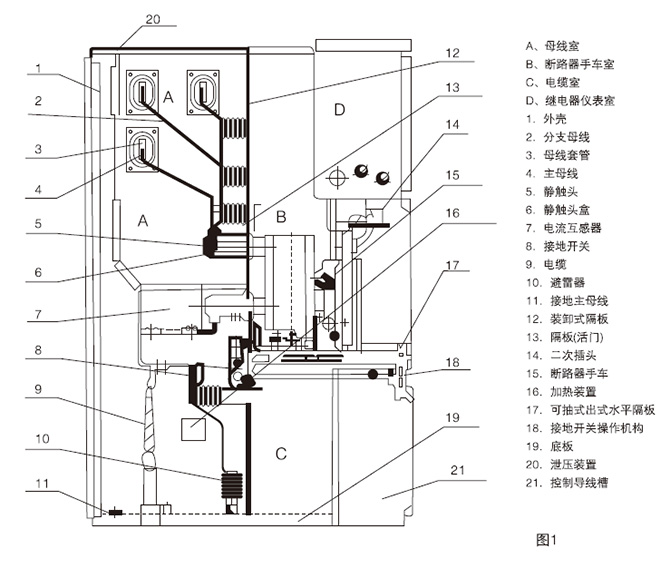

Product Structure

◆ switchgear structure (see Figure 1).

◆ Full metal armor, assembly structure, wide combination regimen.

◆ cabinet made of imported aluminum and zinc plating steel sheet by MlNGE machining, the use of advanced multi-fold process, with rivet nut, bolt connection, high precision and light weight, the degree of high-strength, parts versatility.

◆ Can be equipped VS1-24 series or import VD4 series vacuum circuit breaker, wide applicability, high reliability, maintenance-free for many years to achieve.

◆ handcart set to work, test location, each location has to locate and display device, safe and reliable.

◆ Used by all types of building blocks modulus change, to ensure that the car can be freely interchangeable with the specifications, with no specifications of the car must not enter.

◆ grounding switch installation

a. in the middle of loading (Front) after the cabinet for easy maintenance overhaul sided (Figure -1a).

b. in the rear loading (Rear) to facilitate the wall to save space area (Figure -1b).

◆ Current Transformer Installation:

a. After the cabinet room of the cable being installed.

b. Bend the bottom of a large plate lifting.

◆ cable compartment can be equipped with up to nine single-core cables.

◆ hyperbaric chambers are each relief channel, ensure personal safety.

◆ highly reliable interlock device, fully meet the "Five Anti" safety requirements.

◆ transported by special truck trolley, easy operation, and flexible.

◆ front door with observation windows, can easily observe the working status of interior components.

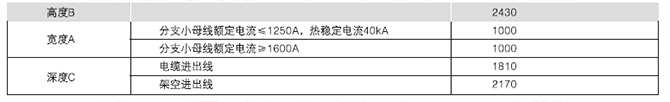

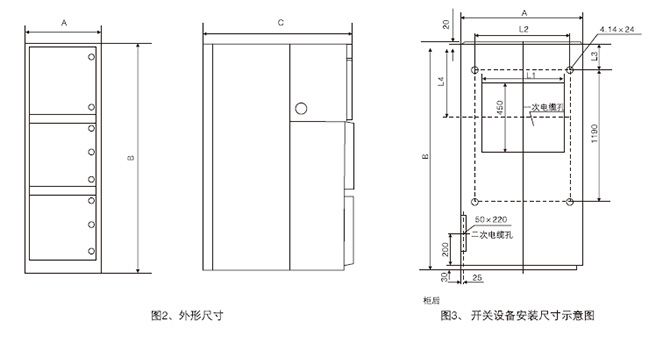

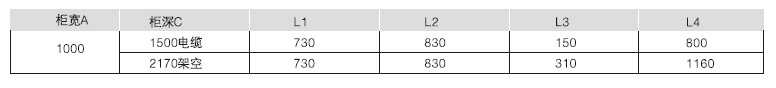

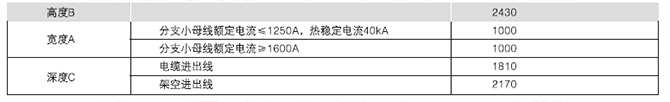

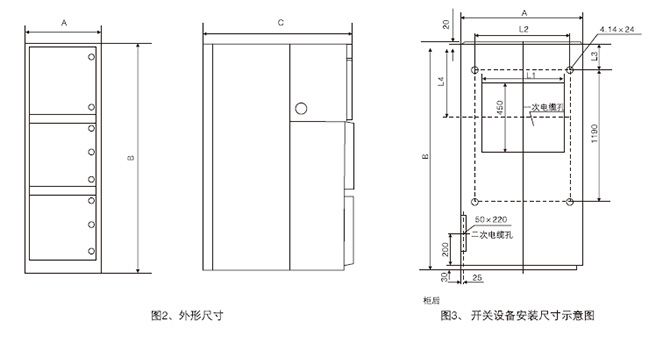

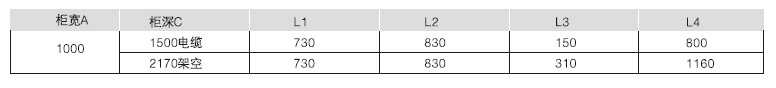

Dimensions (see Figure 2, Table 3)

Dimensions (see Figure 2, Table 3)

Transportation, installation and commissioning

· Transport and Storage Considerations

a, product handling, transportation allowed tipping, inverted and subjected to severe vibration, slings should be placed in boxes or switching equipment designated site;

b, to prevent rain, in order to avoid product moisture;

When c, switching equipment arrived at the scene, the consignee shall inspect the goods packaging is intact, whether the goods damaged or missing, notify the supplier if necessary to jointly inspect the scene;

d, shelving products should be smooth, not disassemble electrical components and parts.

· Switching equipment installation

a, the basic framework surface should be smooth and the floor above the 2 ~ 4mm, frame flatness and straightness tolerances of 1mm / m;

b, on the basis of the frame by one in order to adjust the position of the switch cabinet stitching, verticality of not more than 2mm. When the switch to more than 10 the number of cabinet from among the best start assembling. Switchgear and base frame base frame with bolted or welded;

c, to facilitate the installation of the main bus switching equipment installation LCL should be installed with the main bus alternately;

d, with pre-installed by grounding busbar switchgear cabinets main ground bus, grounding device will switch the main ground bus and power distribution room very connected;

After e, and secondary cable once the installation is complete, to plugging the gap around the cable glands and installed seal plates and separators.

Debugging · switchgear

a, inspection and quarantine contacts and insertion depth contact is good;

After b, switching equipment installed to conduct operational tests, manually operated circuit breakers, trolley and grounding switches and other components, and check the operation of all mechanical linkage program, the action to be accurate, no card phenomenon should be flexible;

maximum, minimum operating voltage of mechanical properties c, check the circuit breaker meets the requirements to operate in accordance with the provisions of the test, combined points should be normal;

d, the secondary loop current test to check the correctness of the protection, control and signal circuits actions;

e, the main loop resistance measurement, loop resistance of the circuit breaker should not exceed the standard specified value;

f, the main circuit between white and relatively frequency voltage withstand test, carried out according to the provisions of the transfer and acceptance;

g, the secondary circuit dielectric strength test 2000V / 1min. There should be no breakdown flashover. Secondary circuit electronics part, the test voltage agreed by the user and manufacturer.

Switching equipment maintenance and repair

Equipment / components (such as wearing parts) inspection and maintenance intervals, depending on its length running time, the frequency of operation and fault situations, such as breaking. Depending on the operating conditions and site environment, every 3 to 5 years for switching equipment to conduct an inspection and maintenance.

• Press the vacuum circuit breaker manual requirements, check the operation of the circuit breaker and operating mechanism, and make the necessary adjustments and lubrication;

• Check trolley into the car, the bus the whole process of working conditions, adjust and lubricate if necessary;

· Check the interlock device is flexible and reliable; adjust and lubricate as necessary;

• Check the dynamic and static isolation contact contact surfaces without damage, the insertion depth to meet the requirements, whether the spring pressure weakened, surface coating without abnormal oxidation and replace obsolete conductive paste on isolating contacts;

• Check the bus and the exposure of each conductive connection parts and fastening, surface heating phenomenon found to be processed;

• Check the ground loop section circumstances, such as exposure to ground contact, the main ground wire and grounding wire to get married, to ensure the continuity of its conductivity;

· Wipe the dust vacuum interrupter and insulation surface with a soft cloth. As a result of condensation resulting in partial discharge phenomena, may be coated with a thin layer of grease discharge surface as a temporary repair.

Random files

Product certification;

· Factory inspection report;

· Installation instructions;

· Secondary wiring diagram;

· Packing List

· Special tools;

· The main components of the switching device's instruction manual and other technical documents and attachments.

Ordering Information

· The main circuit of Figure number, use and single-line system diagram Rated voltage Rated current Rated short-circuit breaking current, power distribution room layout and arrangement of equipment, such as switches configuration diagram.

· Switchgear require control, measurement and protection functions and requirements and other automatic locking device.

· Switch the main electrical components inside the device model, size and quantity.

· If required bus line counters or bridge connection between switching equipment, provides bus rated ampacity of the bridge, the bridge spans the bus, from the ground height data and other specific requirements.

· Switching equipment used when special environmental conditions, should be specified when ordering.

· Other special requirements.