Outline

HXGN17-12 type box-type fixed metal-enclosed switchgear (referred to as RMU), rated voltage of 12kV, rated frequency 50Hz AC high voltage equipment unit, primarily for phase AC ring network, terminal distribution network and industrial electrical equipment , from the acceptance, distribution of power and protection and so on, it is also suitable for loading box-type substation.

In line with GB3906 "3.6 ~ 40.5 AC metal-enclosed switchgear and control equipment", in line with international standards IEC298 "AC metal-enclosed switchgear and control equipment" requirements. And with the "Five Anti" interlock function.

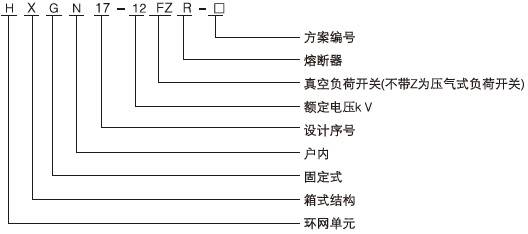

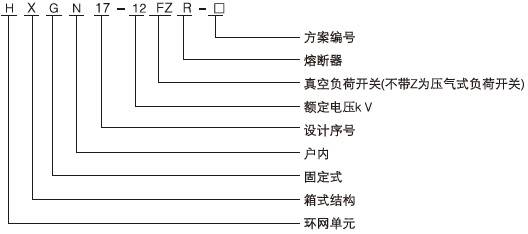

Model and meaning

Conditions of Use

· Ambient temperature limit + 40 ℃, the lower limit of -25 ℃;

· Altitude not more than 1000m;

· Relative humidity on average less than 9% 5, on average less than 90%;

· No fire, explosion hazard establishments and violent vibration;

· Ambient air pollution no corrosive or flammable gases, water vapor and conductive dust;

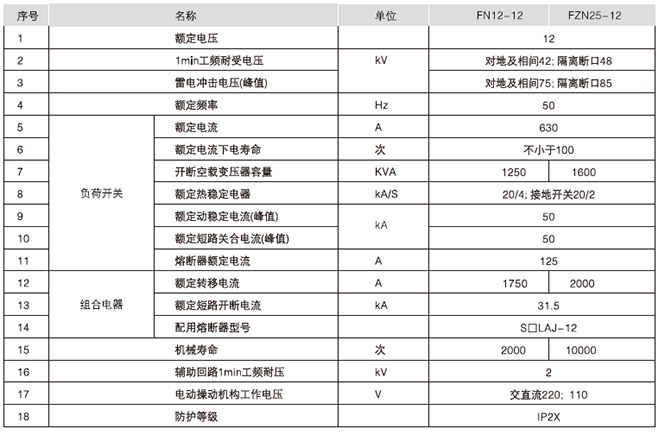

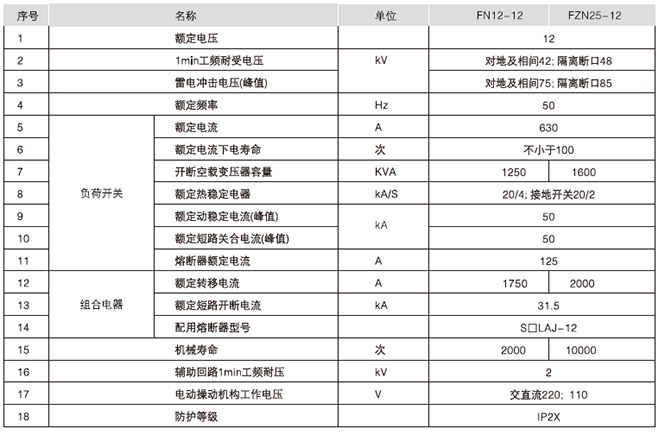

The main technical parameters

Structural features

* Use whole assembly structure, light and beautiful, can be any combination of installation, ease of extension of unlimited expansion.

· Either with FN12-12 type compressor load switch, combinations, can also be equipped FZN25-12 vacuum load switch, combination units. Small size, maintenance-free, three-phase linkage structure, with clear separation fracture.

· Load switch, combinations, its installation flexible and can be mounted left and right side, suits, flip (FZN25 not flip).

Can be manual and electric operation, may have remote control function.

· With a sound and reliable mechanical linkage, interlock device, fully meet the "Five Anti" feature.

. a load when the switch is closed, grounding switch can not switch on the front door can not be opened;

. b opening the load switch, grounding switch can switch on when the grounding switch is closing, the door can be opened;

. c grounding switch is closed, the load switch does not switch on the front door can be opened:

. d grounding switches gate, load switch points, closing the front door can not be opened;

e. power cable into the line next time, when there is electricity in the line, regardless of the load switch in the closing or opening the front door lock control solenoid position, it can not be opened. (Except with a special key to unlock the outside emergency).

· Load switch with linkage protective insulation valve or transparent insulation cover, block live contact, to ensure personal safety.

Adopt a positive operation and maintenance, can be wall mounted.

· Front door with observation windows, cabinet components can be clearly observed working conditions.

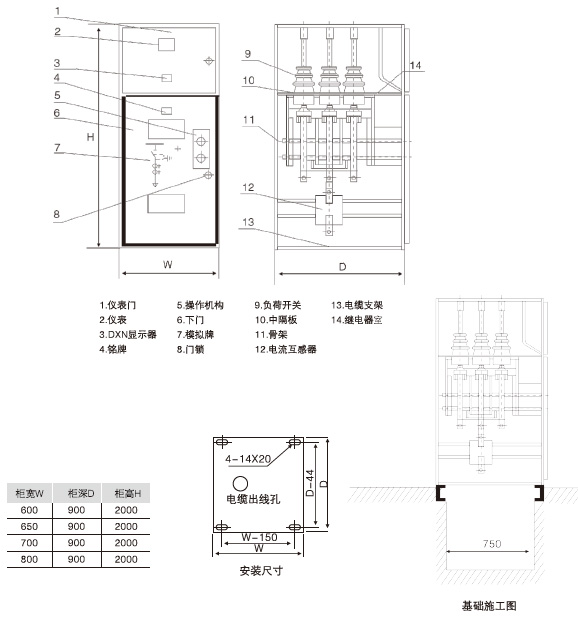

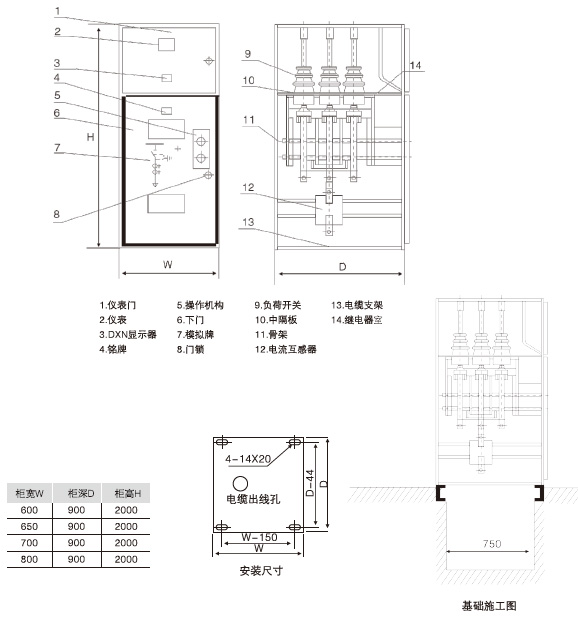

Dimensions

· Dimensions and mounting base with reference to FIG. 1, base channel projecting ground 1-3mm, the roughness should not exceed 1.5mm per meter range, the entire length of not more than 5mm.

· The switchgear on the basis of the order placed, adjust the position of a good installation. Then fixed with M12 bolts or spot welding method between cabinet and cabinet with M8 bolts and tighten.

· Cover installation open the main bus and a cable terminal contact surfaces should be clean and painted a neutral note Vaseline. Note that after installing a cable hole plugging good.

· Cabinet indirectly connected bus, so arranged along the direction of fused switchgear, check the ground if there are any omissions, whether continuous conduction ground loops, grounding resistance should be less than 1Ω.

· Installation of secondary cables, cable entry from the front counter at the bottom, along the side wall into the relay room, tap on the terminal block; or by the introduction of a small bus on the Roof secondary relay room, installed after plugging the cable holes.

· Clean up debris inside the dust.

Commissioning and Operation

· According to the order and specification requirements model checking electrical components mounted cabinet is consistent; check for loose fasteners; check once or twice a wiring is correct; operating load switch, earthing switches, mechanical interlock 3 to 5 times, no catching phenomenon should be flexible, interlocking meet the "five Anti" requirements, then the mechanical moving parts lubrication.

• Press the manual and factory test report to check the insulation level of the switchgear and circuit resistance, mechanical properties of load switch, the test results should be consistent with the factory test report or similar.

· Transmission Operation: Only the door closed and locked, operating grounding switch to "OFF" position, in order to operate the load switch to the closing position, (if there is no ground switch interlock mechanism put the hit "minute" position) .

· Power operation: When the load switch opening in isolated position, to closing the grounding switch, grounding switch in the closing position, in order to open the door, (eg no earthing switch interlock mechanism is put hit "integration" of position).

Note: When incoming cabinet repair, should be cut into the line supply, after opening the load switch, and check the cabinet live shows, after confirming that no electricity, open the door and hang up after the grounding line overhaul.

Maintenance and repair

· Users should periodically perform maintenance and repair switchgear, generally six months or once a year;

• Clean all parts of the dust, especially dust insulation surface;

· Check the mechanical moving parts, regularly filling grease, so that it remains flexible and reliable;

• Check the electrical contact is good contact area, with or without overheating, ground loop is turned on:

• Check the fasteners are tightened.

· Incoming Cabinet overhaul should be cut off at the higher power, after opening the load switch, see the live shows, after confirming that no electricity, repair the door hung open ground.

• When the fuse blows when a short circuit, either one or two blows, it is necessary to replace all three.

· The main component parameters overhaul its instructions.

The factory data and Accessories

Factory supplier should provide the following documents and attachments

· Invoice

· Product certification and factory test report

· Instructions

• For electrical drawings

· The main components of the specification

· Door keys, the operating handle and a single provision of spare parts contract.

Ordering Information

Order should provide the following technical information:

· Main Wiring number, use and single-line system diagram, rated voltage, rated current, rated short-circuit breaking current \ distribution room floor plan and switchgear arranged diagrams;

· Switchgear control, demands and schematics measurement and protection requirements and other lock and automatic device;

Model · switchgear main electrical components, specifications and quantity;

· Switchgear used when special environmental conditions, should be specified when ordering;

· Other special requirements, in order to be a detailed written explanation before consultation.